Integrating traditional ceramic craftsmanship with modern technology, we support SUPOR in creating ceramic cookware that combines wellness concepts, aesthetic design, and practical functionality. Together, we are expanding the high-end kitchenware market and delivering a superior cooking experience to consumers.

We have partnered with the renowned UAE brand Homecentre to co-develop a matcha-green ceramic cookware collection. From glaze formulation and mold design to firing techniques and material innovation, we provide full technical support to ensure perfect harmony in color, texture, and performance. Each piece delivers superior heat resistance, even conductivity, and lasting durability, bringing refined aesthetics and functionality to modern kitchens.

Partnering with German Pool, we have redefined traditional ceramic materials to develop a new IH Induction Heating Casserole. This innovation combines high-efficiency heating, energy conservation, and health safety, bringing a smarter cooking experience to modern kitchens.

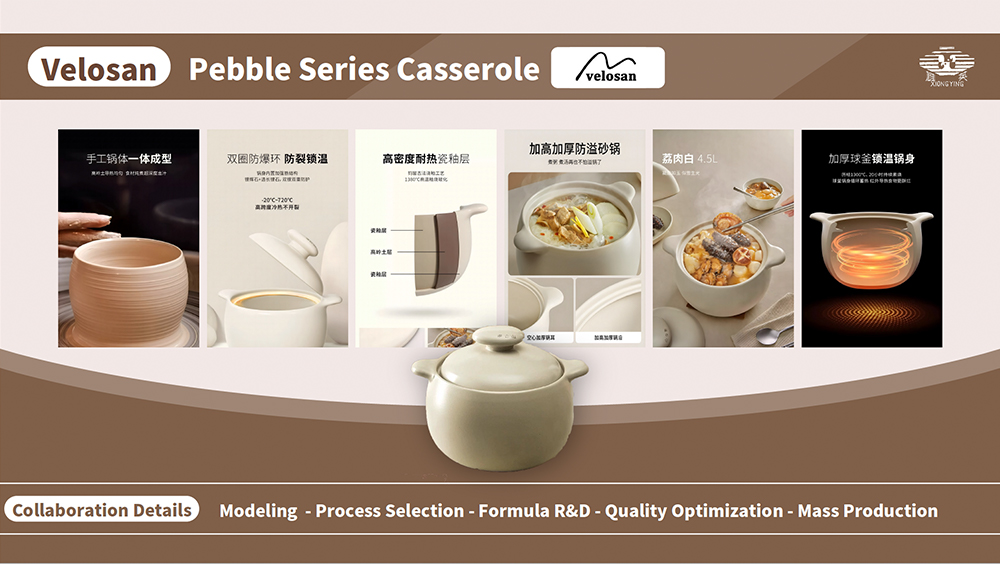

We have established a deep collaboration with Velosan, providing one-stop technical support from mold development and craftsmanship selection to material upgrades and mass production. This ensures that each clay pot features exceptional heat resistance, uniform thermal conductivity, and high durability, meeting the high-end demands of modern kitchens.

We have formed a strategic partnership with Malaysia’s premium home brand OasisHome to launch the Champagne Series Ceramic IH Pot, blending traditional oriental craftsmanship with modern innovation. From mold design and material development to mass production, we participated throughout the process and integrated our proprietary IH-compatible ceramic technology, enabling traditional clay pots to work efficiently with induction cooktops — achieving a true balance of aesthetics and technology.